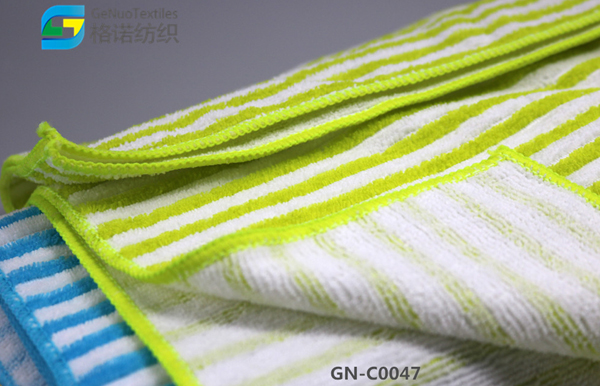

Product Number: GN-C0047

Material: 100% cationic polyester

Size: 35*70cm, 40*40cm, 30*30cm… Customized according to customer requirements

Color: Red, yellow, blue… Customized according to Pantone color codes or samples

Weight per square meter: 280GSM

Uses: For cleaning household, kitchen, car, and electronic instruments

Description and Use:

(1) High absorbency and soft to the touch.

(2) Very durable and easy to clean without detergent.

(3) Contains no chemicals and has no unpleasant odor.

(4) Soft, comfortable, and with a pleasant feel.

(5) Suitable for cleaning various types of cars, kitchenware, furniture, and pet supplies.

Color: As per customer requirements

Packaging: Standard export packaging or customized packaging as per customer requirements

Country of Origin: Jiangsu, China

Payment Method: Bank transfer, Alipay, WeChat

Minimum Order Quantity: 2000 pieces

Contact Person:

Ms. Xiao: +86 18906226220/15306222870 (WeChat)

All-Polyester Cationic Three Red is made from 100% cationic polyester yarn, dyed using cationic three-red dyes (or three-red yarn combination technology), and processed with specialized weaving and finishing. The key feature is the combination of cationic-modified polyester and the three-red color system, offering vibrant color, high colorfastness, abrasion resistance, and wrinkle resistance, suitable for apparel, home textiles, and industrial fabrics.

All-Polyester Cationic: Polyester molecular chains are modified with cationic groups, allowing stable bonding with cationic dyes. Dyeing can be done at room temperature and pressure, producing richer, fuller colors.

Three Red: Two common forms:

Using three different cationic red dyes (e.g., Cationic Red 3R, Red GTL, Red X-5GN) in a single bath to create layered red shades.

Three-red yarn combination: three red cationic yarns are woven with other yarns in cycles, producing a textured three-red effect.

Raw material: 100% cationic polyester yarn, common counts 20-32s, single filament 1-3 denier, strength ≥3.8 cN/dtex, elongation 25-35%, abrasion- and wrinkle-resistant, shrinkage ≤3%.

Cationic modification improves dye affinity, resulting in wash colorfastness ≥4, rubbing fastness 3-4, ensuring minimal fading after repeated washes. Chemically stable, resistant to weak acids and bases, and mold-free.

| Process Type | Key Points | Advantages |

|---|---|---|

| Three-Red Dye Single Bath | Mix three cationic red dyes (e.g., 3R, GTL, X-5GN) in pH 3-5 acetate bath, dye at room temperature and pressure, followed by reduction wash and setting | Uniform layered red shades, high color richness, efficient and cost-effective |

| Three-Red Yarn Combination | Three red cationic yarns woven with plain or other-colored cationic yarns, knit or woven into fabric | Clear three-red texture, suitable for jacquard, stripes, and decorative patterns |

Weaving: Commonly warp knitting, weft knitting, or plain/twill weaving; needle/warp-weft density adjusted to fabric weight requirements (e.g., knit 14-18 needles, woven 80×60–120×80 threads/inch).

Finishing: Relaxation scouring → alkali reduction (improves hand feel) → cationic three-red dyeing → reduction washing (remove floating dye) → soft setting (160-180℃), improving dimensional stability and softness.

| Category | Common Range |

|---|---|

| Fabric Weight | Knit: 120-200 g/m² (apparel); Woven: 180-300 g/m² (home textile/industrial) |

| Width | Knit: 150-180 cm; Woven: 145-160 cm, customizable |

| Hue | Bright red, maroon, wine red; three-red combination shows layered red tones with no visible color difference |

| Wash Durability | Home ≥200 washes, Commercial ≥300 washes, exceeding ordinary polyester |

| Air Permeability | Knit ≥500 mm/s; Woven ≥300 mm/s, suitable for different applications |

Outstanding Color: Three-red combination with cationic polyester delivers rich, layered red tones with high colorfastness, visually superior to regular polyester, suitable for applications requiring high color quality.

Durable and Easy Care: Polyester material is wrinkle- and abrasion-resistant; cationic structure resists pulling; maintains shape and avoids pilling after repeated washing, extending lifespan.

Quick Drying and Easy Cleaning: Hydrophobic polyester and open/plain textures enhance airflow; dries in 1-2 hours; easy to wash off stains; minimizes bacterial growth.

Cost-Effective: Room temperature and pressure dyeing reduces energy; three-red dye/yarn combination is mature and efficient for mass production, overall cost lower than cotton-dyed fabrics.

Apparel: Sportswear, outdoor clothing (quick-dry, abrasion-resistant), casual wear (vibrant colors), uniforms (wrinkle-resistant). Three-red shades suitable for festive or special occasions.

Home Textiles: Curtains, cushions, tablecloths; long-lasting color and fade-resistant, ideal for home décor.

Industrial Fabrics: Hotel/restaurant tablecloths, cleaning cloths; frequent washing without damage; three-red maintains neat appearance. Medical/protective fabrics (with antimicrobial treatment) resist disinfectants.

Usage Warnings:

Avoid high temperatures (≥150℃) to prevent fiber softening; do not use bleach or strong acids/alkalis.

Wash dark fabrics separately initially to prevent color bleeding onto other items.

Care Methods:

Wash: Neutral detergent, ≤40℃ water, gentle machine or hand wash, avoid vigorous scrubbing.

Dry: Air dry in a ventilated area; avoid direct sunlight; low-temperature ironing ≤110℃ keeps fabric flat.

Replacement Cycle: Apparel 6–12 months; home textile/industrial use 1–2 years depending on wear.

This website uses cookies to ensure you get the best experience on our website.